Insulated Panels

Liner panels have one metal skin surface with polystyrene foam board adhered to it for better insulation. In the past 20 years, end-users, contractors and consultants have become increasingly aware of the losses associated with thermal transmission.

The outer and inner metal skins of Insulated Panels conform to the same specifications as the single skin painted panels described above. In addition, Insulated Panels have a factory injected polyurethane core. Thermal transmission data can be found in the Zamil Steel Technical Manual on Pre-Engineered Buildings.

Insulation of various types is now used in all types of buildings. Zamil Steel was one of the first companies to introduce polyurethane sandwich panels in the Middle-East. Polyurethane has been recognized as the most resistant material to heat transmission.

Insulation of various types is now used in all types of buildings. Zamil Steel was one of the first companies to introduce polyurethane sandwich panels in the Middle-East. Polyurethane has been recognized as the most resistant material to heat transmission.

Ex & Dx Liner Panel

Ex & Dx Liner Panel DatasheetSize: 202.35 KB

Zamil Steel Type Dx and Type Ex panels feature an outside flat surface with concealed fasteners providing a rich and smooth appearance for your external building walls and interior roof and wall liners.

The sides of adjacent panels form an interlocking tongue-and-groove system concealing the fasteners. This enhances the building's appearance and improves its security.

Quick and Easy Installation

The insulating board, laminated to the inside surface of the panel, increases its rigidity and makes handling of the panel much easier. One side of the panel is fixed to the interlocking groove of the adjacent panel, whereas the other side is fastened to the secondary system of the wall resulting in faster and easier installation.

TEMPCON Sandwich panels

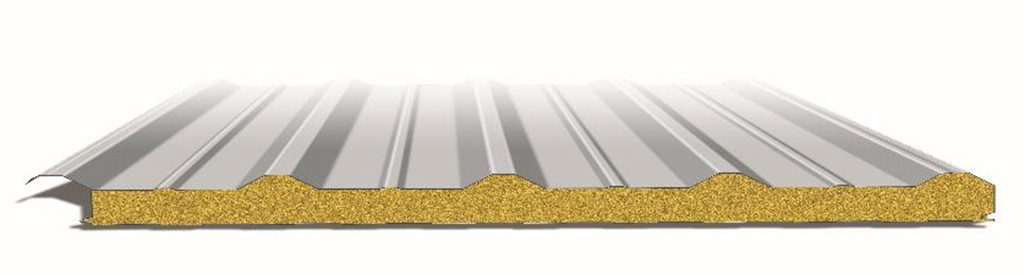

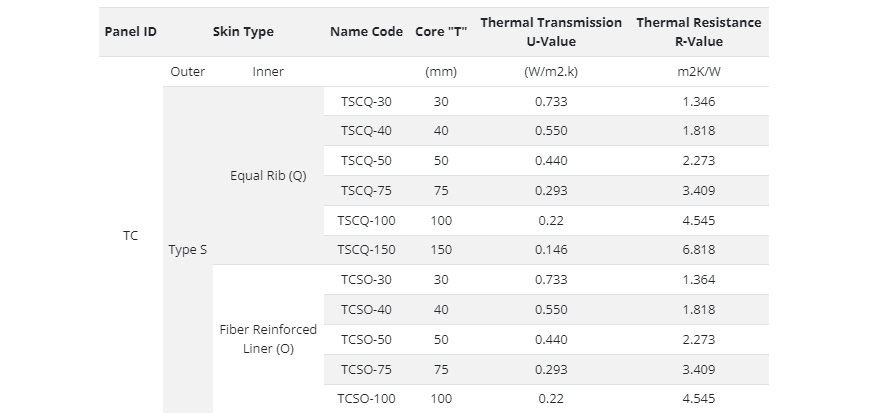

Tempcon sandwich panels (TCSQ) that are produced using rigid Polyisocyanurate (PIR) foam core with external and internal sheet in steel or aluminum and profile of outer skin is Type-S1 & profile of inner skin is Type-Q.

TCSQ panels are suitable for roof and wall of all building applications.

Dimensions & Thicknesses

Tempcon sandwich panel is available in a single outer profile type in both steel and aluminium in combination of the below listed inner skin types; the insulating core can be produced in various thicknesses and thermal insulation values.

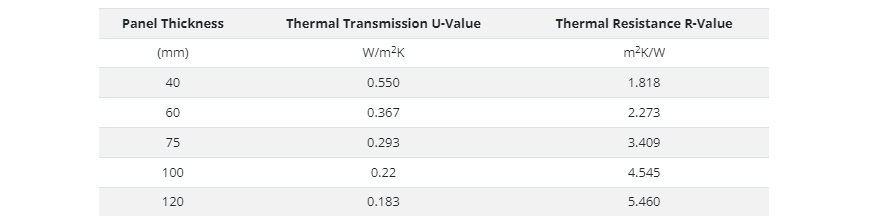

Thermal Properties

TEMPARCH Sandwich panels

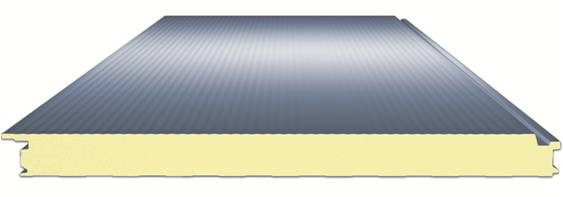

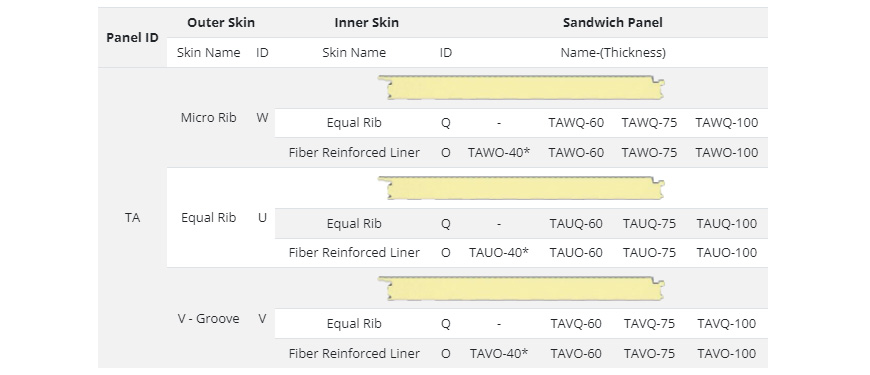

Temparch Sandwich panels (TA) are aesthetic wall panels also produced using rigid Polyisocyanurate (PIR) foam core with external and internal sheet in steel or aluminum.

Temparch sandwich panels have a unique detail to conceal fasteners and are therefore more suitable for walls & interior partition in showrooms, hypermarkets, shopping malls and commercial buildings.

Dimensions & Thicknesses

Thermal Properties

| Salient features | Application |

|---|---|

|

|